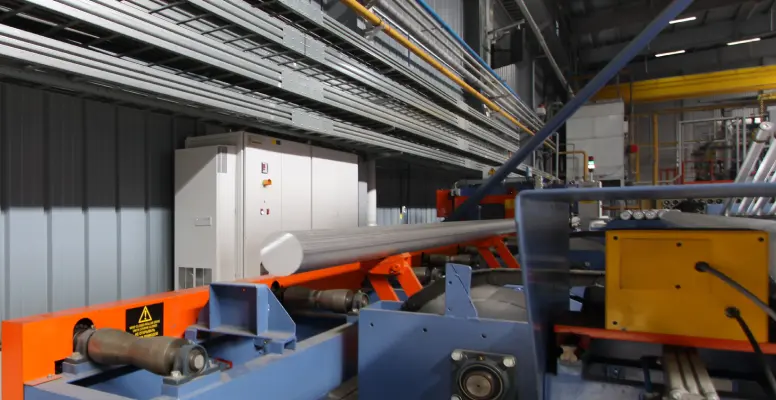

Here aluminium is melted, reduired alloys are prepared. The aluminium billets are automatically cut, marked and sorted, as well as undergo the process of homogenisation and cooling.

The 5, 7 and 9 inch lines ensure high pressing speed, stable geometry and mechanical properties of the profiles.

They provide even profile coating that is highly resistant to heat, UV-rays and corrosion. Chrome-free surface preparation technology, quick colour change system, automatic temperature control and polymerisation process control are used. The coating quality is confirmed by Qualicoat Seaside certificate.

Allows to produce three types of mechanically treated profiles in nine colours: silver, bronze and gold shades. For creating decorative effects on the surface, additional preparation technologies are used: scratching, shot blasting and polishing.

Allows to produce three types of mechanically treated profiles in nine colours: silver, bronze and gold shades. For creating decorative effects on the surface, additional preparation technologies are used: scratching, shot blasting and polishing.

+44 121 824 4788

+44 121 824 4788